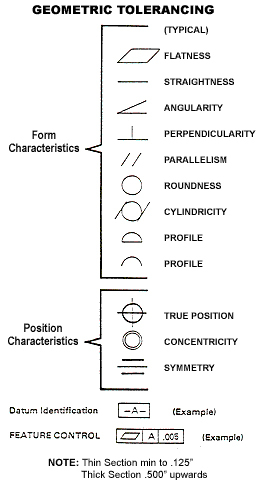

Geometric Tolerances

Tolerance Capabilities

The investment casting process can produce precisely replicated parts in a truly economical fashion. Effective part configuration is the critical element in achieving strict tolerances for investment casting. Milwaukee Precision's team of experts communicates with you at every step of the process - ensuring you of a quality experience that is unparalleled in the investment casting industry.

Straightness, Roundness, & Positioning (holes or bosses)

The standard tolerance is ±.005 per inch for axial straightness, roundness (bar or tube shapes) and positioning of holes or bosses.

Concentricity

The concentricity is dependent on measurements taken from the same plane, and does not include out-of-roundness tolerance. If this is the case, the center of a bore to the outside diameter of a part will be concentric within .003" for each 1/2" of wall thickness.

Angularity

The as-cast angle tolerance is a function of the part design. A minimum tolerance of ±1/2 degree is considered standard.

Blind Holes and Slots

Blind holes and slots can be cast, assuming that the depth is equal to the width or diameter for small characteristics less than 3/8". When depth sizes increase above 3/8", the size of the opening will be incrementally doubled.

Flatness

Flatness is measured as the distance between two parallel planes, within which the entire surface of the part must lie. The shape of the part will influence the cooling behavior of the wax pattern and the part as it solidifies. This tends to determine the process capability, which is frequently expressed in terms of six square inches of surface area. The chart below shows general flatness guidelines based on part thickness.

Wall Thickness

The standard minimum wall thickness for investment casting lies between .040" and .080". Wall thickness as low as 0.020" has been achieved within a small area. Overall wall thickness is dependent on the alloy used and the size of the surface area.

| Part Thickness | Flatness T.I.R. | ||||

| .000" to .500" | .004" | ||||

| .051" to 1.000" | .008" | ||||

| 1.000" to 2.000" | .15" |

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.