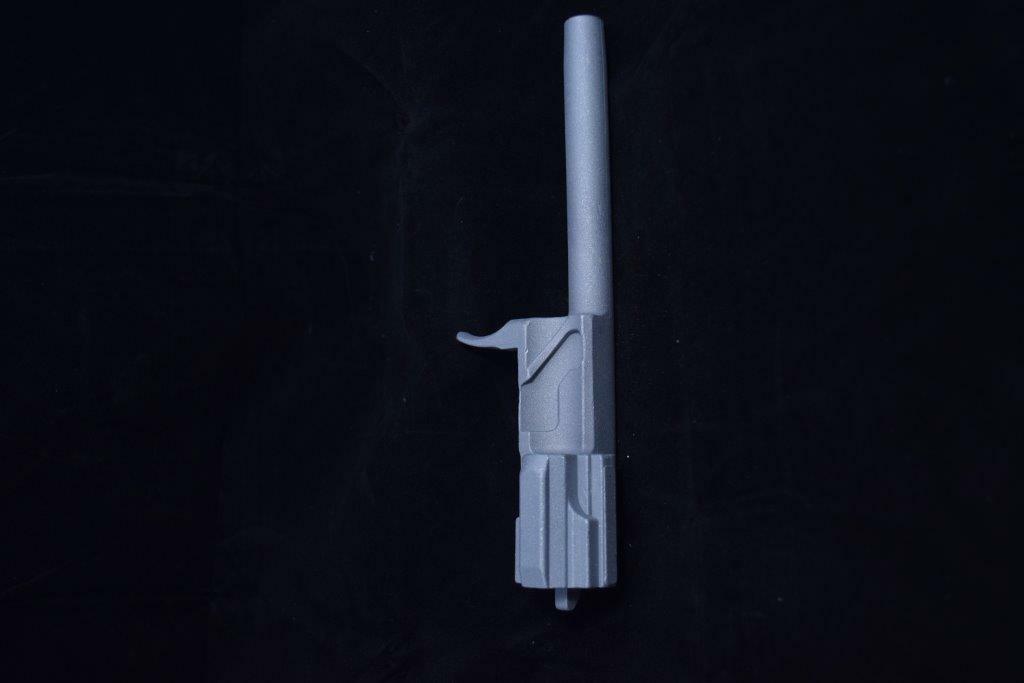

17-4 SS Alloy Castings

Manufacturers needing to produce stainless steel components with intricate geometries frequently turn to investment casting due to its superior integrity and accuracy, particularly with high-performance alloys such as 17-4 PH stainless steel. Milwaukee Precision Casting is a leading provider of investment casting services and has the equipment and experience to produce high-performance stainless steel investment castings for a range of industries. Milwaukee Precision Casting has the experience to deliver the 17-4 stainless steel investment castings in the quantities you need at a price that will work within your manufacturing budget. Contact us today for a quote.

What is Investment Casting?

An outgrowth of one of the oldest known metal forming techniques, investment casting has been used in some form for roughly 5,000 years and is a proven solution for manufacturers needing a part with complex internal geometries. Wax patterns from injection dies are repeatedly immersed, or “invested,” in a ceramic slurry that hardens around the wax. Once the ceramic is hardened, the coated wax melted away in a furnace, leaving the ceramic shell intact. Molten steel is then poured into the ceramic, and the ceramic shell is removed to reveal the final part.

Additional Characteristics of 17-4 ss casting:

17-4 PH stainless steel casting is known for exceptional hardness, durability, and corrosion resistance under extreme temperatures. Because of this, it’s frequently used in the aerospace, oil & gas, defense, and automotive industries. Common applications for 17-4 stainless steel include:

- Pumps

- Valves

- Gears

- Paper mill equipment

- Missile and aircraft fittings

- Chemical process equipment

Why Choose Milwaukee Precision Casting?

Don’t trust your stainless steel investment casting to anybody but the best! With nearly 30 years of experience, Milwaukee Precision Casting has a range of options and certifications to produce the 17-4 investment castings you need:

- Can handle high-volume or short run projects

- Capable of manufacturing complex cast components up to 50 lbs

- Rapid prototyping available

- ISO and ITAR certified facility

In many cases, the investment casting process offers enough precision to produce a finished part requiring no additional finishing work. However, to achieve the most precise tolerances, we offer post-casting finishing work. In addition, we offer a complete range of secondary options for your investment castings, including heat treatment, non-destructive testing, and assembly.

Contact us today for a custom quote!

Additional Stainless Steel Grades

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.