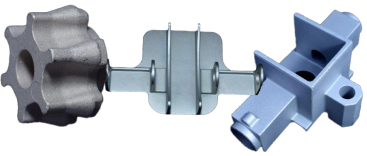

Casting Materials

Milwaukee Precision Casting, Inc. can produce precision investment casting products in virtually any air-melt alloy. From simple cast steel components to highly complex aluminum cast components our investment casting facility can meet your material needs, exacting precision for the military, firearms, medical and aerospace industries.

Investment Casting Foundry

Milwaukee Precision Casting, Inc., a leading precision investment casting foundry in Wisconsin, began manufacturing investment castings in 1993. Throughout our history, we have taken pride in our ability to partner with clients to solve their casting problems in innovative, cost-effective ways.

Whether you require complex cast components weighing just a few grams or large components of up to 50 pounds, or your needs include high volume, rapid prototype or short-run projects, you can count on the experience, innovation and dedication of Milwaukee Precision Casting to work for you.

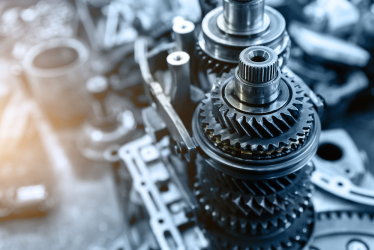

Full-Service Casting Capabilities

Our office is accompanied by our full-service foundry, capable of fulfilling your custom needs. By partnering with us for your investment casting projects, you will benefit from the experience and capabilities of an industry leader.

Milwaukee Precision Casting, Inc. offers a variety of services to ensure the quality and longevity of all of our investment casting products. Our heat treatment solutions include annealing for machinability, normalizing for material stress relief, and hardening for durability and wear resistance. For quality assurance, we conduct non-destructive testing such as x-rays, Grade A x-rays, HIPing (or hot isostatic pressing), magnetic particle inspections, and fluorescent penetrant inspection.

As for custom finishing touches, Milwaukee Precision Casting, Inc. handles all plating and surface treatments. This includes phosphate coating, burnishing, hand polishing, passivation, pickling, and electro-polishing.

Industries Served

Milwaukee Precision Casting, Inc. has provided investment casting solutions for quality-minded companies in a wide variety of industries, including: