Investment Castings

What is an Investment Casting?

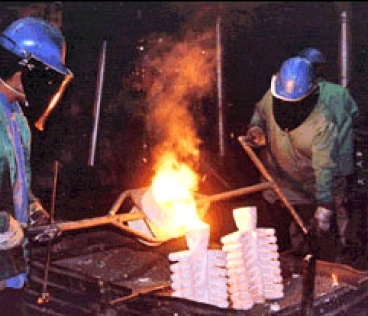

Investment casting refers to the ceramics formed around the wax patterns to create a casing for molten metal to be poured. Once the wax patterns are created, they are melted onto a gate system, dipped into slurry and sand to form a layered casing, and then replaced with melted metals such as stainless steel, aluminum, carbon steel, brass, bronze, and much more. Below are some short videos with some of the steps in the investment casting process.

How are Investment Castings Made?

Developing investment castings involves creating an original wax pattern, coating the image with plaster and building of successive layers until a strong shell envelopes the model. After melting out the wax, molten steel, stainless steel or bronze will be poured into the mold, creating a perfect duplicate of the original wax pattern. Compared to machining apart, investment casting can economically offer undercuts, high definition, complex detail and a smooth surface finish.

Most often, investment casting is the only way a part can be economically manufactured.

Frequently Asked Questions

Investment castings are used in a wide range of industries, including firearms, food service, gas and oil, as well as the energy industry. While these are some of the industries served through investment casting, they are not the only ones served by Milwaukee Precision Casting. Investment castings can be used for almost anything where steel, aluminum, brass, and many other materials are required.

Milwaukee Precision Casting can offer a wide range of finishing work including: Machining, Heat Treating, Non-Destructive Testing, Polishing, Passivation/Electropolishing, Deburring/Ball Burnishing, Laser Etching, Coating, Packaging, and more depending on the needs of any part. Milwaukee Precision Casting has close relationships with many local vendors to allow for the best possible part at the lowest possible price.

The difference in strength between castings and other methods of metal working, while there, are negligible. Investment castings have been used by the military, aerospace, and medical fields for many years, and are still used in those industries today. Through testing and thorough inspection, we can ensure that no part that leaves Milwaukee Precision Casting would not meet the most rigorous of requirements.

The Investment Casting Process

Click on any of the steps below for detailed information on the investment casting process.

To download the complete casting process guide, please click here.

What Are Lost Wax Investment Castings?

By injecting wax into a permanent-molding die to form wax patterns, investment casting are the solution for many complex parts that are required in large quantities. We produce investment castings in lost wax patterns from a few grams up to 40 pounds, and can economically produce low quantities with manual tooling, or high volumes utilizing multi-cavity automatic molding tools.

The origin of the lost wax investment casting, also known as the lost wax process, stretches back in time to 1100/1700 BC. Works were created from hand sculptured wax patterns with delicate detail. During the post – WWII period, this process evolved and expanded into virtually every industry and marketplace, as seen today.

Investment Casting Material Properties

Search properties by adjusting the filters below.

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.