Rapid Prototype Investment Casting

Milwaukee Precision Casting, Inc. has the capability of producing prototype investment castings in 2-3 weeks to prove out the design of a part without the expense of hard tooling.

Our Prototyping Abilities

3D Scanning To Capture Part Geometry

We use our 3D scanner to capture the geometry of a customer supplied sample part or wax pattern. With further software processing, the part can be replicated using our 3D wax printer. We also have the ability to generate a CAD file based on the geometry. The CAD file can be used to manufacture a metal die to create wax patterns and also to generate an engineering drawing if needed.

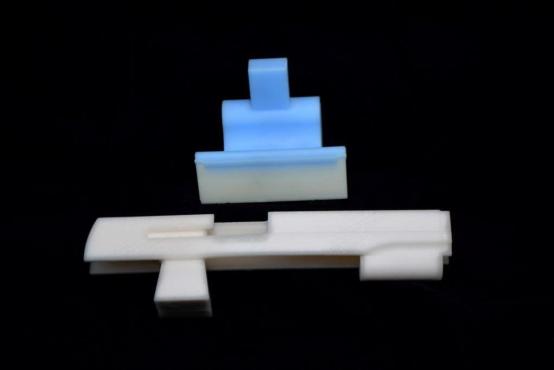

3D Print Patterns In 1 Day

Computer models of parts are converted directly to 3D wax patterns that will be used in our investment casting process. Patterns can generally be made in one day, saving the time and money associated with making a metal die. The 3D printer also gives the flexibility to produce multiple variations of a part for evaluation.

CAD Software To Keep Projects Moving Quickly

We have the ability to quickly produce drawings from models or make changes to existing models to help keep projects moving quickly.

Please contact us and let us know how we can serve your rapid prototype casting needs.

Quick, Cost-Effective Investment Casting Prototypes

We understand the demand to produce castings quickly for our customers, but still provide a high-quality product. Besides being a quick, cost-saving investment casting option, below are some of the benefits for prototype investment casting.

- Tight dimensional tolerances

- Complex and cored geometries

- Greater design freedom

- Larger alloy selection

- Little to no machining or finishing because of the casting process

Material Capabilities

For rapid prototyping investment casting, you're able to choose from a wide selection of metals! Milwaukee Precision Castings is not only capable of creating prototypes from common metals such as Stainless Steel, Carbon Steel, Brass, Bronze and Cobalt, but we also have the experience and capabilities to deal with handling complex investment casting prototypes including Aluminum and Bronze.

Rapid Prototype Casting Gallery

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.