Carbon Steel Investment Castings

Looking for cost savings? Carbon steel investment castings may be the answer. Because we provide carbon steel investment cast parts to net shape, we can eliminate most, if not all secondary machining operations.

Providing a net shape to typical casting tolerances of +/-.005" per inch, Milwaukee Precision Casting, Inc. has proved time and time again that sand castings, forgings, and machined components can be converted to carbon steel investment castings with significant cost savings.

Unsure about your part design? Check out our prototyping capabilities

Popular Carbon Steel Grades

- 4130

- IC 1020

- SAE & MIL-S 4140

- SAE 8620

Carbon Steel Investment Casting Grades

| Alloy | Common Usage | Applications |

1018 & AISI 1020 |

The 1000 series is the softest of the three common carbon steels will more likely bend rather than break under intense pressure. They are commonly used to make cranks, handles, and braces. | |

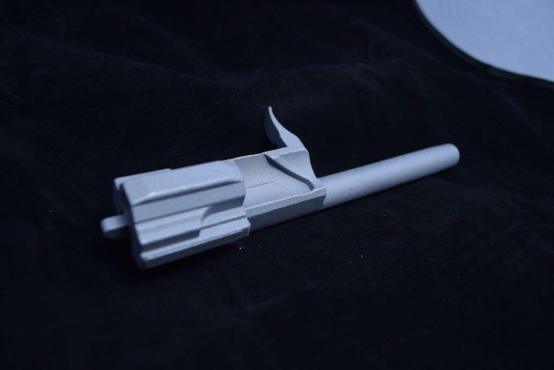

4130SAE 4140 & 4140 MIL-S |

The 4100 series is a high strength material that is used when deformation of a part is not allowed. They are commonly used to cast firearm components and ratchets. | |

SAE 8620 |

The 8600 series steel is the middle ground between 4100 and 1000 series. 8600 series is stronger than 1000 series but will bend prior to breakage. They are commonly used to cast firearm components, housings, and nozzles. |

Machining, Testing & Treating

We also have the capabilities of furnishing secondary operations such as machining, non-destructive testing, heat treat, and assembly. Our cosmetics are as good as any foundry can offer, better than most.

Please contact us and let us know how we can serve your carbon steel investment casting needs.

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.