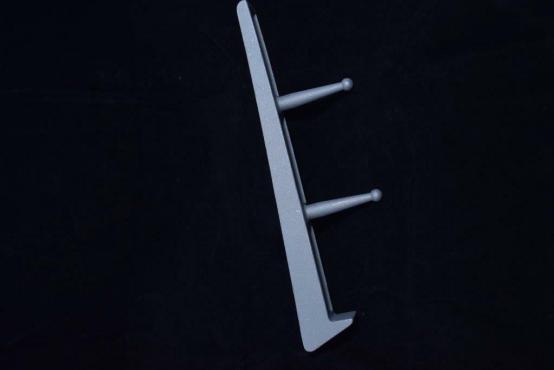

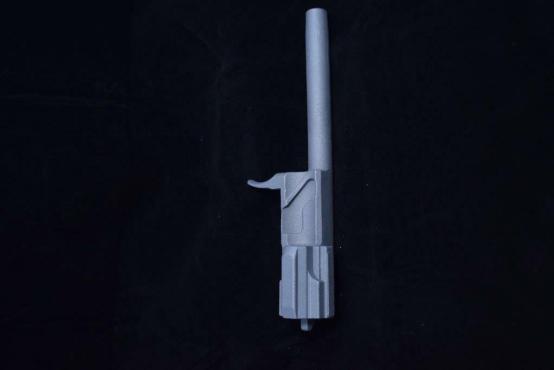

Stainless Steel Investment Castings

Milwaukee Precision Casting, Inc. has experience pouring a wide variety of stainless steel investment cast parts. We cast stainless steel from miniature to 50 pounds.

The most common alloys we have poured are 304, 316, and 17-4 stainless steel. We are also capable of pouring other air melt alloys upon your request. Specific material chemistry and mechanical specifications will be provided to you if needed. For your Stainless Steel Investment Casting & Cast Part needs, Milwaukee Precision Casting, Inc. can help you out.

Popular Stainless Steel Grades

What are the Advantages of Stainless Steel Investment Castings?

Stainless steel's biggest advantage is its excellent corrosion resistance. Unlike other materials, stainless steel investment castings have a built-in chromium oxide layer that provides exceptional anti-corrosive properties. These corrosion-resistant properties make stainless steel castings ideal for military, medical, and industrial applications.

Unsure about your part design? Check out our prototyping capabilities

Commonly Cast Stainless Steel Alloys

| Alloy | Common Usage | Applications |

| 304 | Food grade steel, housings, bodies 304 is widely accepted in the food industry as the standard for cleanliness as well as corrosion resistance. |

|

304L/316L |

Similar to other 300 series steel, the "L" stands for low carbon, making it softer but more corrosion resistant for each grade of material. | |

| 316 | Housings, gears, plates 316 is known for its superior corrosion resistance, making it ideal for many uses including marine environments. |

|

410 & 416 |

Housings, bushings, handles, brackets 400 series steels are high strength and very machinable. They will tend to break rather than bend under intense pressure |

|

| 17-4 | Rods, pins, links, arms 17-4 is the strongest of the stainless steel family and is used on parts that cannot bend.. |

Why Choose Milwaukee Precision Casting as Your Stainless Steel Casting Manufacturer?

When it comes to finding the best stainless steel casting manufacturer, quality and precision is everything. Milwaukee Precision Casting is an ISO and ITAR certified investment casting foundry, equipped to produce investment castings at various stainless steel grades, including 304, 316, and 17-4.

As a full-service foundry in Milwaukee, Wisconsin, we can provide corrosion resistant stainless steel castings from 1/10 of an ounce to up to 50 pounds, with an accuracy rate of 0.005 per inch. With some of the most competitive lead times in the entire industry and over 30 years of experience, you can trust our team to produce highest quality stainless steel castings.

To request a quote for your stainless steel casting project, fill out our form or give us a call today!

Certifications & Compliances

Milwaukee Precision Casting, Inc. is committed to delivering the highest quality stainless steel investment castings. Our various certifications support our strict quality standards and testing and inspection capabilities.

- ISO 9001:2015 Certified

- Mil-I-45208 Standards for Military Applications

- ITAR (International Traffic In Arms Regulations)

- AMS Certified Non-destructive Testing

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.