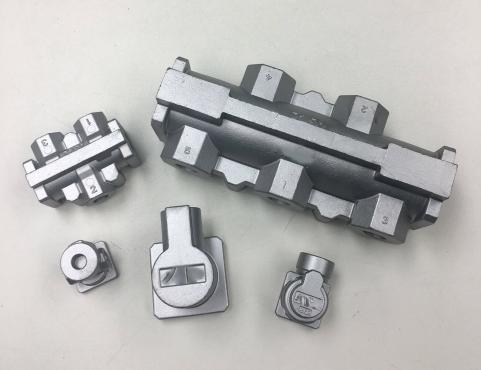

Oil & Gas Castings

Investment castings used in the oil and gas industry require the highest degree of quality, durability, and corrosion resistance. Milwaukee Precision Casting produces stainless steel castings used in applications such as ramps, heavy-duty locks, flame and flow control, and even material removal fingers. We can cast a higher internal geometry using our wax pattern process. We also verify our castings using x-rays and any customer-requested requirements.

Milwaukee Precision Casting specializes in stainless steel castings, specifically 17-4 and 316 grades. These materials have the highest corrosion resistance. However, if an oil & gas application requires hardening we suggest using 17-4 stainless steel.

Oil & Gas Casting Components

Milwaukee Precision produces various parts for this industry including:

- Process Control Instruments

- Field Machinery Components

- Valve Bodies

- Control Bodies & Covers

- Burner Management

- Wear Insects

- Ramps

- Feed Fingers

- Drill tiles

Investment Casting Materials We Offer:

Questions?

Ask Our Team

Give us a call or fill out the form below and our team will be in touch soon.